What To Know About Aluminum Brake Calipers

If the engineers of your vehicle decided to use aluminum for the body of the calipers on your vehicle, they were probably more focused on performance than they were on the cost to manufacture. Aluminum calipers enhance the performance of a vehicle by reducing “un-sprung weight”, which helps acceleration and handling. Aluminum calipers also retain a cleaner look since they are less prone to corrosion. On the other hand, cast-iron calipers can have a rusty look.

Besides cost of manufacturing and care during installation, there aren’t many downsides to aluminum calipers. Other than those 2 items, the life expectancy and their function are pretty much the same as their cast iron counterparts.

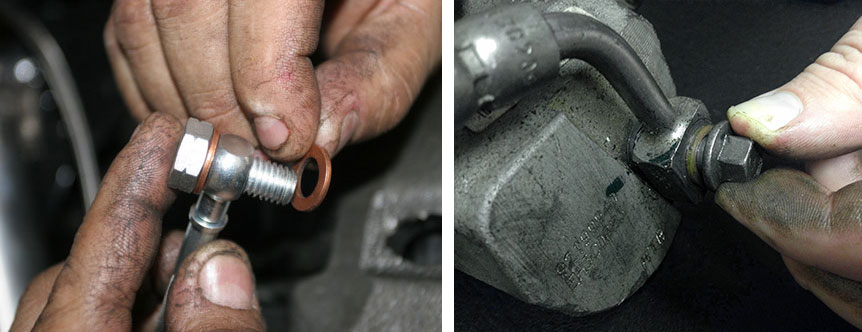

One thing to keep in mind is that aluminum is much softer than cast iron or other metals. So, when installing aluminum calipers, make sure to only finger-tighten all fittings (Banjo bolt, bleeder screw, etc.). Then, use a torque wrench to finish-tighten to the vehicle manufacturer’s specifications.

This is very critical because those fasteners are made from hardened steel and will very very easily strip out threads in an aluminum caliper if overtightened.

What Materials Are Brake Calipers Made From?

Brake calipers are crucial components component of brake systems. They are made from durable materials because they must hold up under extreme conditions.

Calipers are subjected to:

- Extreme heat generated from braking

- Hydraulic pressure

- Severe road conditions

Cast Iron Brake Calipers

Cast iron has been historically used by manufacturers to make brake calipers. It is very strong, cost-effective, and stress-resistant. With the proper coatings, it is also resistant to corrosion. Although cast iron calipers are durable and rarely need to be replaced, they are heavier, so aluminum calipers have become popular alternatives.

Aluminum Brake Calipers

Aluminum brake calipers are excellent alternatives for cast iron. They are strong, stress-resistant, and do not rust. While meeting the demands of modern vehicles, aluminum brake calipers are also significantly lighter than their cast iron counterparts. This reduced weight improves both fuel economy and ride quality. Another benefit of aluminum calipers is increased thermal conductivity – this means that heat inside the caliper can be conducted out and dissipated rather than continue building.

Signs You May Need to Replace Your Brake Calipers

While certain components of a braking system – such as brake pads – are intended to wear out over time with normal use, brake calipers are designed to last the life of the vehicle. However, calipers don’t always make it that long. Below are common signs that you may need to replace your brake calipers.

Leaking Brake Fluid

Today’s braking systems rely on hydraulic pressure to operate. If a caliper is leaking, you may notice an oily spot on the ground, near the inside of the tire. However, leaking brake fluid may not be related to a leaky caliper at all. If you cannot determine the cause of the leak, a trained technician can diagnose and repair the problem for you.

Unevenly Worn Down Brake Pads

If you notice that the brake pads are thinner on one side of the vehicle than the other side, it is possible that a faulty brake caliper is to blame. However, bad brake calipers aren’t the only reason why brake pads wear unevenly, so it will be important to diagnose the true cause of the issue. A repair technician can help.

Vehicle Pulls To One Side When Driving or Braking

If you feel your vehicle pull to one side while driving or braking, it could be a sign of a faulty caliper. Brake calipers contain pistons that move in and out due to hydraulic pressure. When corrosion or debris causes the caliper pins or caliper pistons to get stuck, a brake pad will either fail to make contact with the rotor or fail to release the rotor. If the brake pad fails to make contact with the rotor, the vehicle will pull away from the side with the faulty caliper. If the brake pads fail to release the rotor, the vehicle will pull toward the side with the faulty caliper. This can occur while driving the vehicle or when applying the brakes.

Have a Question? PowerStop Can Help

At PowerStop, our mission is to provide top-quality performance brakes for every vehicle on the road. If you have a question regarding any of our products, contact us today online or toll-free at (888) 863-4415. Our customer service team is available to answer your questions Monday through Friday from 8 a.m. to 5 p.m. (CST). Se habla español.

Back