- All PowerStop Products (37)

- Brake Kits (10)

- Brake Kits with Calipers (5)

- Brake Pads (10)

- Brake Shoes (3)

- Brake Rotors & Drums (4)

- Brake Calipers (2)

- Brake Hoses (1)

- Brake Sensors (1)

- Track Day (4)

- Big Brake Kits (1)

- New ProductPowerClear™ Wiper Blades

Recommended for You

Brake Pad & Rotor Kits

Sorry, no products matching your vehicle were found in this category.

Sorry, no products matching your vehicle were found in this category.

Z36 Truck & Tow Brake Upgrade Kit

Brake Upgrade for Trucks and 4x4s that tow, haul or off-road

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z23 Evolution Sport Brake Upgrade Kit

Brake Upgrade for the Daily-Driver

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z26 Street Warrior Brake Upgrade Kit

Brake Upgrade for Muscle Cars and High-Performance Vehicles

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Jeep Big Brake Conversion Kit

Big Brake Conversion Kit for your off-road adventure Jeep

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z17 Evolution GEOMET® Fully Coated Rotor Brake Kit

Stock Replacement Upgrade for the Daily-Driver

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z23 Evolution Sport GEOMET® Fully Coated Rotor Brake Kit for European Vehicles

Stock Replacement Upgrade for Daily-Drivers of European Vehicles

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z17 Stock Replacement Brake Kit

Stock Replacement

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

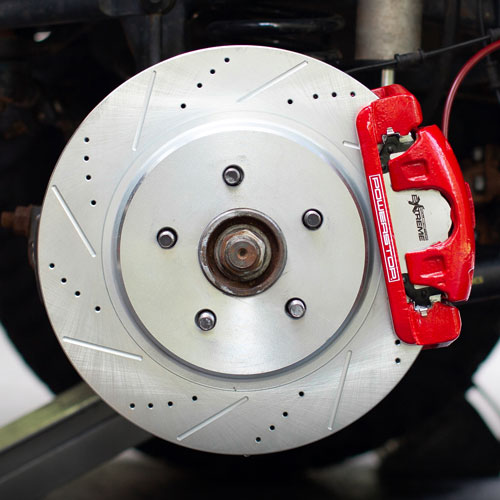

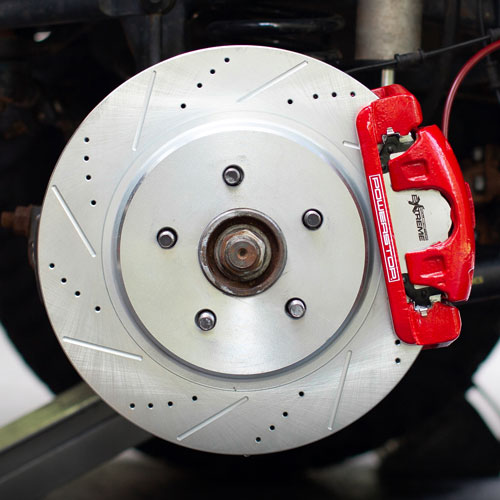

Track Day Brake Kit

Stage 1 Brake Upgrade Kit for Beginning Track Day Enthusiasts

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Track Day Spec Brake Kit

Stage 2 Brake Upgrade Kit for Advanced Track Day Enthusiasts or SPEC racing

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Euro-Stop Brake Kit

Stock Replacement for European Vehicles

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Brake Caliper Kits

Sorry, no products matching your vehicle were found in this category.

Sorry, no products matching your vehicle were found in this category.

Z36 Truck & Tow Brake Upgrade Kit with Powder Coated Calipers

For trucks and SUVs that are used to tow or haul at least once per year, or for off-roading.

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z23 Evolution Sport Brake Upgrade Kit with Powder Coated Calipers

Brake Upgrade for the Daily-Driver

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z26 Street Warrior Brake Upgrade Kit with Powder Coated Calipers

Brake Upgrade for Muscle Cars and High-Performance Vehicles

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Jeep Big Brake Conversion Kit

Big Brake Conversion Kit for your off-road adventure Jeep

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z17 Stock Replacement Brake Kit with Calipers

Stock Replacement

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Brake Pads

Sorry, no products matching your vehicle were found in this category.

Sorry, no products matching your vehicle were found in this category.

Z36 Truck & Tow Carbon-Fiber Ceramic Brake Pads

For trucks and SUVs that are used to tow or haul at least once per year, or for off-roading.

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z23 Evolution Sport Carbon-Fiber Brake Pads

For the daily driver who wants to upgrade the stopping power of their car, truck or SUV.

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Next Gen Carbon-Fiber Ceramic Brake Pads

Super-Premium Brake Replacement / Upgrade

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Next Gen Euro Carbon-Fiber Ceramic Brake Pads

Super-Premium Brake Replacement / Upgrade

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z26 Street Performance Carbon-Fiber Ceramic Brake Pads

Brake Upgrade for Muscle Cars and High-Performance Vehicles

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z17 Evolution Ceramic Brake Pads

Stock Replacement for Cars, Trucks and SUVs

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z16 Evolution Ceramic Brake Pads

Stock Replacement for Cars, Trucks and SUVs

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

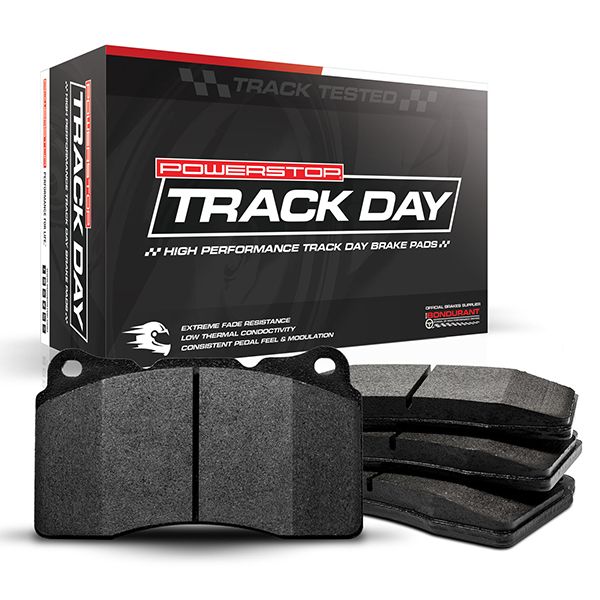

Track Day Brake Pads

Stage 1 Brake Pad for Beginning Track Day Enthusiasts

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Euro-Stop ECE-R90 Brake Pads

Stock Replacement for European Vehicles

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Track Day Spec Brake Pads

Stage 2 Brake Pad for Advanced Track Day Enthusiasts or Spec Racing Series

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z37 Top Cop Carbon-Fiber Ceramic Brake Pads

Brake Upgrade for Fleet and Pursuit Vehicles

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Z47 Medium Duty and Fleet Carbon-Fiber Semi-Metallic Brake Pads with Hardware Kit

Designed as an upgrade over stock brakes to provide long-lasting performance for fleet vehicles running full GVW on a daily basis.

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Brake Rotors

Sorry, no products matching your vehicle were found in this category.

Sorry, no products matching your vehicle were found in this category.

Evolution Drilled, Slotted & Zinc Plated Rotors

Brake Upgrade for Cars, Trucks and SUVs

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Evolution Genuine GEOMET® Fully Coated Rotors

Stock Replacement Upgrade

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

OE Stock Replacement Rotor

PowerStop Autospecialty brake rotors provide a direct fit solution for original equipment fit and performance.

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Semi-Coated Rotor

Semi-Coated Rotor designed to match OE specifications

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Brake Shoes

Sorry, no products matching your vehicle were found in this category.

Sorry, no products matching your vehicle were found in this category.

Autospecialty Brake Shoes

Stock Replacement for Cars, Trucks and SUVs

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Autospecialty Parking Brake Shoes

Stock Replacement for Cars, Trucks and SUVs

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Autospecialty Brake Shoes with Hardware

Stock Replacement for Cars, Trucks and SUVs

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Calipers

Sorry, no products matching your vehicle were found in this category.

Sorry, no products matching your vehicle were found in this category.

Powder Coated Calipers

Brake Upgrade for the Daily-Driver

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Autospecialty Stock Replacement Calipers

Stock Replacement for Cars, Trucks and SUVs

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Pad Wear Sensors

Sorry, no products matching your vehicle were found in this category.

Sorry, no products matching your vehicle were found in this category.

Electronic Brake Wear Sensors

Stock Replacement for Cars, Trucks and SUVs

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Brake Hoses

Sorry, no products matching your vehicle were found in this category.

Sorry, no products matching your vehicle were found in this category.

Stainless-Steel Braided Brake Hoses

Performance Brake Upgrade for Cars, Trucks and SUVs

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site

Big Brake Conversion Kits

Sorry, no products matching your vehicle were found in this category.

Sorry, no products matching your vehicle were found in this category.

Jeep Big Brake Conversion Kit

Big Brake Conversion Kit for your off-road adventure Jeep

Will not fit your vehicle

Will not fit your vehicleCUSTOMIZE THIS KIT OPTIONAL

KIT TYPE

CHOOSE WHERE TO BUY

We’ll link you to this exact product on the retailer’s site