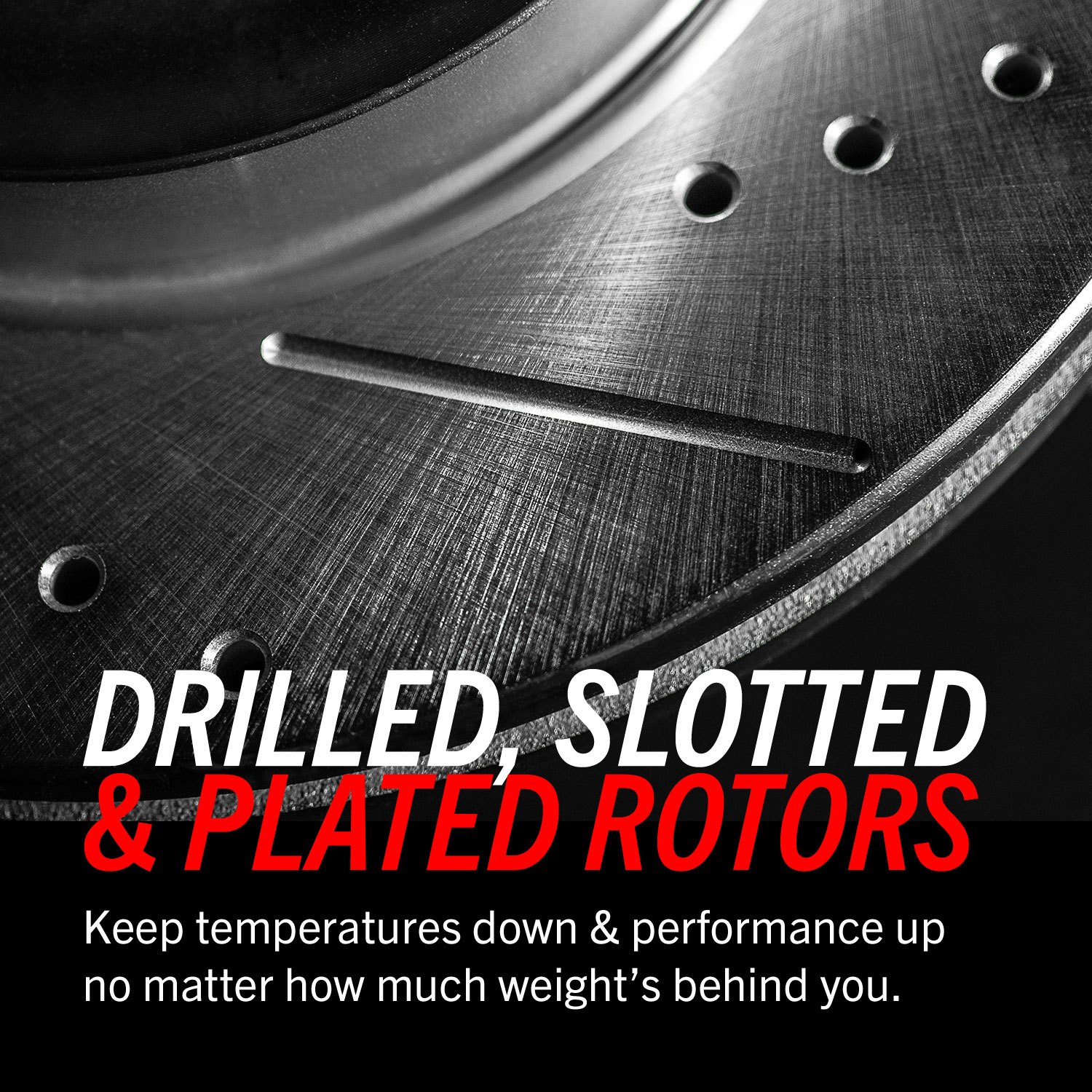

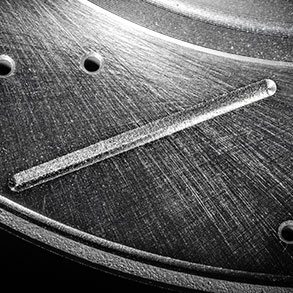

Evolution Drilled, Slotted & Zinc Plated Rotors

Will not fit your vehicle

Will not fit your vehicle

- Drilled & Slotted Rotors

Provides maximum rotor cooling - Plated using Silver Zinc-Dichromate

For maximum protection against rust and corrosion - 100% Mill Balanced

Each Evolution Drilled & Slotted rotor is checked and balanced for safe, smooth braking performance.

& Zinc Plated Rotors

Brake

Upgrade

PowerStop drilled and slotted rotors provide a bolt-on upgrade for improved brake cooling and performance. Precision cross-drilled for maximum cooling and maximum performance during extreme conditions. The rounded slots sweep away gas, debris, and moisture to keep a clean friction contact patch on the rotor surface providing smooth, safe braking. Silver zinc dichromate plating resists rust and corrosion. With a direct OE fit, there are no special modifications needed. Upgrading the looks and stopping power of your vehicle has never been easier.

- Brake Upgrade

- Daily-Driving

- Cars

- Trucks

- SUVs

Designed to Perform as a Kit

Designed to Perform as a Bundle with PowerStop Brake Pads

WHAT YOU

NEED

TO KNOW

INSTALLATION OPTIONS

Install It Yourself

In the world of vehicle maintenance, replacing your brakes is an easy job to tackle on your own. Our step-by-step installation guides will help you get the job done.

How To Guides Questions? Contact Technical Support [email protected]Take it to a Pro

Not confident in your abilities as a mechanic? No problem! We have a network of installers that are ready to help you out. Bring in your car and your brake kit, and they’ll do the rest.

Find an InstallerBREAK-IN PROCEDURE

Break-In is critical for optimal performance

The break-in procedure is critical to brake performance. The reason for a proper break-in is to establish an even layer of friction material deposited on the rotors from the brake pads. It is very important that this initial layer of friction material is evenly distributed.

Break in your PowerStop Brakes as follows:

-

1

Complete 5 moderate to aggressive stops from 40 mph down to 10 mph in rapid succession without letting the brakes cool and do not come to a complete stop. If you're forced to stop, complete the stop and either shift the vehicle into park or give room in front so you can allow the vehicle to roll slightly while waiting for the track light. The rotors will be very hot and holding down the brake pedal will force the brake pad to contact the rotor and possibly create an imprint on the rotor. This imprint may contribute to the creation of brake judder.

-

2

Continue the break in by completing 5 moderate stops from 35 mph to 5 mph in rapid succession without letting the brakes cool. You should expect to smell some resin as the brakes get hot. After this is complete, continue to drive the vehicle for as long as possible without heating the brakes excessively and without coming to a complete stop (Try for about 5 minutes at moderate speed). This is the cooling stage.

-

3

Once this is completed and the brakes have cooled to standard operating temperature, you may use the brakes normally. Never cool your brakes with water, as this can damage them.

Important

Following proper break-in procedure for new brake pads/rotors using the pad bedding procedure as follows. Proper pad bedding can prevent rotor warping.

WARRANTY & RETURNS

90 Day / 3,000 Mile Warranty

PowerStop LLC warrants this product to be free from defects in materials or workmanship for 90 days from the purchase date or 3,000 miles of use, whichever occurs first. The product, when properly installed in the type of vehicle prescribed, and in which a material or workmanship defect is found, will be exchanged free of charge if returned to the seller who is authorized to service this warranty. PowerStop LLC is not responsible for its products when they are subjected to misuse, abuse, improper application, improper installation, or accident. This 90-day/3,000-mile warranty excludes failure of components due to disc thickness variation (DTV*), usually indicated by brake pulsation. Normal wear is not covered by this warranty.

TECHNICAL SPECS

Daily-Driver, Performance Upgrade

The PowerStop Difference