The braking system is the most important safety feature of your vehicle, making it absolutely crucial to know if your brake rotors are bad. If your rotors are not functioning properly, you may not be able to stop your vehicle in time to prevent a collision.

So, how do you know if your rotors need to be replaced? This comprehensive guide will answer your questions and help you better understand your rotors.

Signs that Your Rotors Are Bad

Recognizing the signs of bad brake rotors is crucial for maintaining the safety and performance of your vehicle. Here are some key indicators that your rotors may be in poor condition:

- Vibration or Pulsating Sensation: One of the most common signs of a bad rotor is a vibration or pulsating feeling in the brake pedal or steering wheel when you apply the brakes. This is typically caused by rotor disc thickness variation (DTV), where the surface of the rotor is uneven.

- Visible Grooves or Score Marks: Upon visual inspection, if you notice deep grooves, score marks, or rough spots on the rotor surface, this indicates significant wear. These grooves can compromise the rotor’s ability to interact effectively with the brake pads.

- Excessive Rust: While some surface rust on rotors is normal, particularly after rain or humidity, excessive rust can indicate deterioration. If the rust is deep and affects the overall structure and surface of the rotor, it can impair braking performance. PowerStop’s Drilled & Slotted Rotors are plated with silver zinc dichromate for maximum protection against rust and corrosion.

- Blue Coloring: Overheating of rotors can cause them to develop a blue tint. This discoloration is a sign of excessive heat exposure and can lead to the rotor becoming warped and less effective.

- Brake Pad Wear: Uneven wear of the brake pads can sometimes be attributed to bad rotors. If the rotors are not smooth or are warped, it can lead to uneven pad wear, which in turn affects braking efficiency.

- Poor Brake Performance: If the vehicle is taking longer to stop than usual, or if the braking feels uneven or less responsive, this could be a sign that the rotors are not in good condition.

- Rotor Thickness: Over time, the surface of the rotors wears down, reducing their thickness. If the rotor becomes too thin, which you can often check with a micrometer, it needs to be replaced. The edge code on all PowerStop rotors includes the minimum thickness specification.

Read More: Understanding Minimum Rotor Thickness

What Are Brake Rotors and What Do They Do?

Brake rotors are a critical component in a vehicle’s braking system. The primary function of brake rotors is to provide a surface against which the brake pads can press to slow down or stop the vehicle.

When you press the brake pedal, hydraulic fluid is pushed through the brake lines, activating the brake calipers. These calipers then squeeze the brake pads against the rotors. The friction created between the brake pads and rotors generates the necessary force to reduce the wheel’s speed, thereby slowing down or stopping the vehicle.

Brake rotors are designed to absorb and dissipate the immense heat generated by this friction. Good quality rotors are crucial for effective braking as they ensure consistent performance and prevent overheating, which can lead to brake fade (a reduction in braking power).

Moreover, rotors are subjected to extreme stresses and must be robust enough to withstand them without warping or cracking. Over time, however, rotors can wear down, become warped, or sustain damage, which can significantly affect braking efficiency and safety.

In essence, brake rotors are central to a car’s ability to brake effectively. They work in tandem with the brake pads and calipers to ensure that your vehicle can stop promptly and safely when you need it to. Regular inspections and maintenance of brake rotors are vital for the overall health of your vehicle’s braking system and for your safety on the road.

Read More: New Rotors: Transform Your Truck’s Braking Performance

How Do Rotors Work?

The functioning of brake rotors is an integral part of a vehicle’s braking system. To understand how rotors work, it’s essential to grasp the basics of the braking process:

- Activation of the Brake System: When you press the brake pedal, it activates the master cylinder, which in turn pushes brake fluid through the brake lines.

- Hydraulic Pressure: This brake fluid, under high hydraulic pressure, travels to the brake calipers at each wheel.

- Caliper Mechanism: The brake calipers are fitted with brake pads, which are pressed against the brake rotors due to the hydraulic pressure.

- Friction and Heat: The contact between the brake pads and the rotors creates friction. This friction is what slows down the rotation of the wheels. The process of converting kinetic energy (the motion of the vehicle) into thermal energy (heat) through friction is the fundamental principle behind braking.

- Heat Dissipation: Brake rotors are designed to absorb this heat and dissipate it quickly. This capability is crucial because excessive heat can lead to a decrease in braking efficiency, a phenomenon known as brake fade.

- Stopping the Vehicle: As the rotors slow down, they reduce the rotational speed of the wheels, thereby slowing down or stopping the vehicle. The effectiveness of this process depends on the condition and quality of both the brake pads and rotors.

- Release and Reset: When you release the brake pedal, the calipers retract, the brake pads disengage from the rotors, and the wheels are free to turn again. The brake system then resets, ready for the next application of the brakes.

Brake rotors are engineered to provide a smooth, flat surface for the brake pads to act upon. They need to be strong enough to withstand the pressure and heat generated during braking, yet also be able to dissipate that heat efficiently to prevent warping or damage. This balance is crucial for the smooth operation of the braking system and, ultimately, for the safety and performance of the vehicle. Regular inspections and maintenance are necessary to ensure that the rotors remain in good condition and function effectively.

What Causes Brake Rotors to Go Bad?

Brake rotors are a fundamental component of a vehicle’s braking system, but they can deteriorate over time due to various factors. Understanding these factors is key to maintaining effective braking performance. Here are the primary causes of brake rotor degradation:

- Normal Wear and Tear: The most common cause of rotor deterioration is regular usage. Each time the brakes are applied, a small amount of the rotor material wears away due to friction with the brake pads. Over time, this wear can reduce the thickness of the rotors, affecting their performance and safety.

- Excessive Heat and Overheating: During intense braking, especially in high-speed or downhill conditions, rotors can get extremely hot. This excessive heat can lead to warping (rotor deformation), which causes uneven contact with the brake pads and reduces braking efficiency. Overheating can also cause glazing, where the rotor surface becomes too smooth and hard, reducing the friction necessary for effective braking.

- Corrosion and Rust: Rotors are susceptible to rust, particularly if the vehicle is frequently driven in wet, snowy, or salty conditions (like in coastal areas or regions that use road salt during winter). Rust and corrosion can lead to uneven rotor surfaces and compromised structural integrity.

- Impact Damage: Hitting potholes, road debris, or other types of impacts can cause physical damage to rotors, such as cracks, chips, or warping. Such damage can significantly impair braking performance.

- Improper Installation or Maintenance: If rotors are not installed correctly, or if the vehicle’s braking system is not properly maintained (including irregular or improper tire alignment), it can lead to uneven wear or stress on the rotors.

- Use of Low-Quality or Incompatible Brake Pads: Using brake pads that are not suited for the specific type of rotor or are of inferior quality can cause excessive wear or damage to the rotors.

Knowing these causes helps in the early identification of potential issues and timely intervention, either through maintenance or replacement, to ensure the safety and reliability of your vehicle’s braking system. Regular inspections by a qualified mechanic can help identify and address any rotor-related issues before they become significant problems.

Can You Drive with Bad Brake Rotors?

Driving with bad brake rotors is highly discouraged and can be dangerous for several reasons:

- Reduced Braking Efficiency: Bad rotors can significantly compromise the braking performance of your vehicle. This can lead to increased stopping distances, reduced braking power, and in some cases, complete brake failure.

- Increased Wear on Brake Components: Driving with damaged or worn-out rotors can cause excessive wear on other brake components, including brake pads and calipers. This not only leads to inefficient braking but also increases the cost of repairs.

- Vibrations and Unstable Braking: Warped or uneven rotors can cause vibrations through the steering wheel or brake pedal when braking. This can be unsettling and may lead to a loss of control, especially in emergency braking situations.

- Potential for Further Damage: Continuing to drive with bad rotors can lead to further damage to the braking system and potentially other parts of the vehicle. For example, excessive rotor wear can damage the wheel bearings or the suspension system.

- Safety Risks: The most significant concern with driving on bad rotors is the safety risk it poses to you, your passengers, and other road users. The unpredictability of braking performance can lead to accidents, particularly in situations where prompt stopping is crucial.

While a vehicle with bad brake rotors may still be able to move, it is unsafe to drive. The risks far outweigh any convenience or cost-saving measures. It’s crucial to address any brake rotor issues promptly by consulting with a qualified mechanic to ensure your vehicle remains safe and roadworthy.

How Often Should Brake Rotors Be Replaced?

The frequency of brake rotor replacement varies depending on several factors, including driving habits, vehicle type, and the quality of the rotors themselves. However, there are general guidelines you can follow:

- Vehicle Manufacturer’s Recommendations: Always refer to your vehicle’s owner’s manual for specific recommendations. Most manufacturers provide guidelines for brake rotor inspection and replacement intervals.

- Driving Habits and Conditions: If you frequently drive in stop-and-go traffic, mountainous areas, or tow heavy loads, your brake rotors may wear out faster. Aggressive braking habits can also accelerate rotor wear.

- Type of Rotors: The material and quality of the rotors play a significant role in their lifespan. For instance, high-performance rotors or those made from composite materials may last longer than standard rotors.

- Wear and Tear Indicators: Rotors should be replaced if they show signs of significant wear, such as deep grooves, cracks, warping (which causes vibration during braking), or if they have reached the minimum thickness recommended by the manufacturer.

- Regular Inspections: Regular brake inspections by a professional are crucial. A mechanic can measure the thickness of the rotors and check for wear patterns, warping, and other issues that might necessitate replacement.

- After a Brake Pad Replacement: In some cases, especially if the old brake pads were heavily worn, it might be necessary to replace the rotors when you replace the brake pads. When new pads are installed, we recommend turning the rotors if they are within spec. If the rotors cannot be turned, they need to be replaced.

Read More: Why Is It Important to Replace Brake Pads and Rotors at the Same Time?

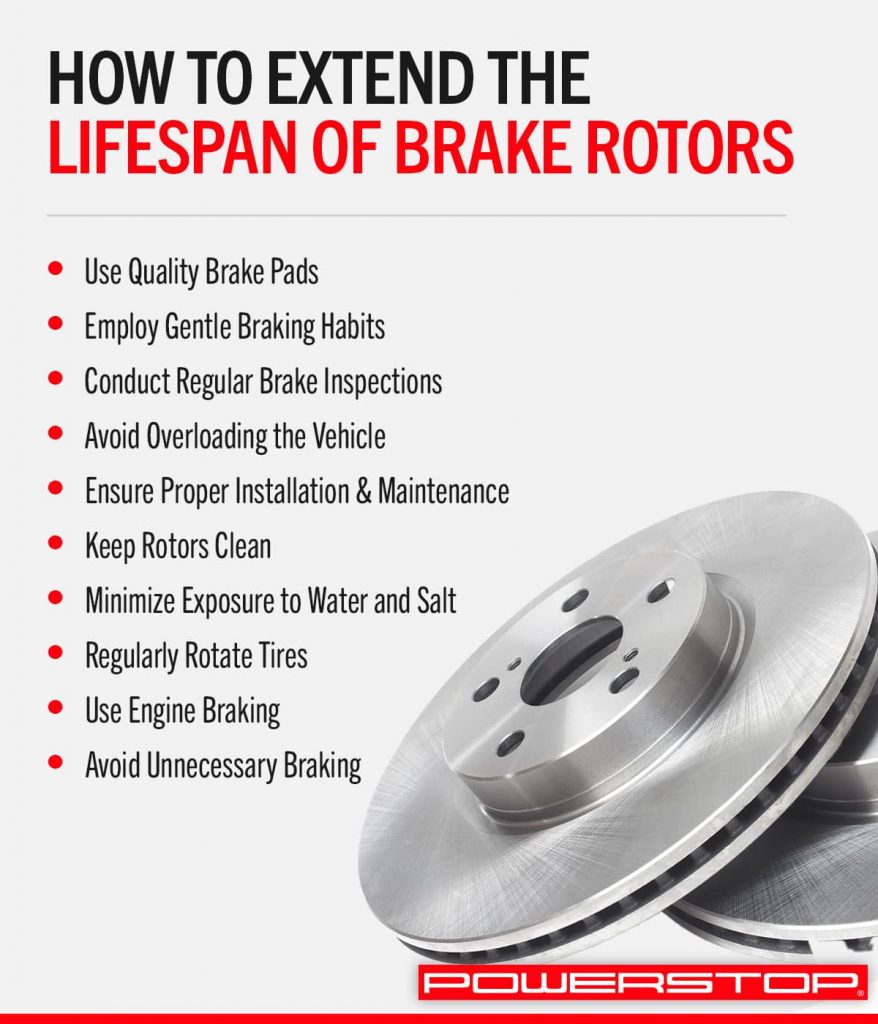

How to Extend The Lifespan of Brake Rotors

Extending the lifespan of brake rotors is crucial for both safety and economic reasons. Proper care and maintenance can prevent premature wear and reduce the need for frequent replacements. Here are some strategies to help extend the life of your brake rotors:

- Gentle Braking Habits: Adopt a driving style that avoids sudden, hard braking whenever possible. Anticipate stops and apply brakes gently and gradually. This reduces the amount of heat generated during braking, which is one of the primary causes of rotor wear.

- Regular Brake Inspections: Have your braking system, including rotors, pads, and fluid, inspected regularly by a professional. This can help identify issues early, before they lead to more significant damage or wear.

- Quality Brake Pads: Use high-quality brake pads. Cheaper pads can wear down rotors faster due to their abrasive materials. Higher-quality pads not only last longer but are also gentler on the rotors. PowerStop’s Z36 Truck & Tow Carbon-Fiber Ceramic Brake Pads are an ideal choice. They blend carbon-fiber and ceramic materials, ensuring that you get clean, severe-duty stopping power with precise control and minimal noise.

- Avoid Overloading the Vehicle: Adhere to your vehicle’s weight limits. Excess weight puts additional strain on your braking system, leading to quicker wear of both pads and rotors.

- Proper Installation and Maintenance: Ensure that rotors are installed correctly and that the entire brake system is properly maintained. This includes making sure that the wheels are torqued to the manufacturer’s specifications and that the wheel bearings and suspension components are in good condition.

- Keep Rotors Clean: Regularly clean your rotors to remove dirt, grime, and rust. This can be done during tire rotation or brake pad inspection. Clean rotors ensure maximum contact with brake pads and help prevent uneven wear.

- Minimize Exposure to Water and Salt: Try to avoid driving through deep puddles or in environments with excessive road salt, as these can accelerate rust and corrosion on the rotors.

- Regularly Rotate Tires: Tire rotation helps ensure even wear on all four tires, which can contribute to more balanced braking and less stress on any one rotor.

- Use Engine Braking: When appropriate, use engine braking (shifting into a lower gear to allow the engine to help slow the vehicle) to reduce reliance on the brakes, particularly during downhill driving. This helps reduce heat build-up in the rotors.

- Avoid Unnecessary Braking: Avoid “riding the brakes” (keeping your foot on the brake pedal without significant pressure) and frequent braking when it’s not necessary, as this can cause heat build-up and wear.

By following these tips, you can help extend the life of your brake rotors, maintain optimal braking performance, and ensure the safety of your vehicle. Regular checks and maintenance are the key to catching any issues early and addressing them before they lead to more serious problems.

Have a Question? PowerStop Can Help!

PowerStop is dedicated to providing top-quality performance brakes for nearly every vehicle on the road. If you have a question about any of our products, contact us today online at [email protected] or toll-free at (888) 863-4415. Our customer service team is available to answer your questions Monday through Friday from 8 a.m. to 5 p.m. (CST). Se habla español.

Back