Brake calipers are an integral part of the braking system. It is an essential component in decelerating the wheels and bringing the vehicle to a stop.

Below, we explore the functionality, components, types, materials, and maintenance of brake calipers.

What Are Brake Calipers?

Brake calipers play a pivotal role in a vehicle’s braking system. They are responsible for slowing or stopping the car by creating friction with the brake rotors. This system is crucial for safe driving, as it directly affects the vehicle’s stopping ability. When the brake pedal is pressed, brake fluid enables the caliper to apply pressure to the brake pads, which in turn press against the rotors, creating the necessary friction to slow down or stop the vehicle.

Brake Caliper Components

Brake calipers comprise several components, including:

- Caliper and Mounting Bracket: The caliper is the part of the brake system that houses the brake pads and pistons. Its primary function is to slow the car’s wheels by creating friction with the brake rotors. The mounting bracket is a sturdy piece that holds the caliper in place over the rotor. It must be strong enough to handle the forces exerted during braking.

- Slide Pins: Slide pins are fixed to either the caliper body or the anchor bracket. These are how the caliper slides and compresses the pads into the rotor when the brake pedal is activated.

- Locking Bolts: These bolts secure the caliper to the mounting bracket. They need to be properly torqued to ensure the caliper remains firmly in place during braking, as any movement could affect braking efficiency and safety. It’s a good idea to add blue threadlocker to the lock bolts to avoid from the lock bolts backing out over time due to road vibration.

- Dust Boots: Dust boots protect the slide pins and caliper pistons from dust, debris, and moisture. Keeping these components clean is crucial for their smooth operation and longevity.

- Brake Mounting Clips: These clips hold the brake pads in place within the caliper. They help reduce vibration and noise and ensure that the pads can move freely when the brakes are applied and released.

- Brake Pads and Shims: Brake pads are the friction material that presses against the rotor to slow down the vehicle. Shims are placed behind the brake pads to help prevent noise and to ensure even wear. Good quality brake pads and shims are vital for effective braking and noise reduction.

- Brake Piston: The brake piston is what pushes the pads against the brake rotor when you apply the brakes. It must move freely within the caliper cylinder.

- Bleeder Screw: The bleeder screw is a screw with a hole in the base and the top to allow the brake system to be bled of any air. Having an airtight system is crucial to the stopping ability. The bleeder screw tightens down and the hole in the base creates a seal with the chamfer in the caliper body. When the screw is loosened slightly, fluid and air are able to pass through its internal channel and out the top.

Each component plays a crucial role in the overall functioning of the brake system, and regular maintenance is necessary to keep them in good working condition. This includes checking for wear and tear, ensuring proper lubrication, and replacing any damaged parts. Properly functioning calipers are essential for safe and effective braking.

Types of Brake Calipers

There are primarily three types of brake calipers:

Floating Calipers

A floating caliper is designed to move slightly side-to-side relative to the rotor. It differs from fixed calipers by having one or more pistons on only one side of the rotor, allowing it to move laterally. When the brakes are applied, hydraulic pressure from the brake fluid pushes these pistons outward, pressing the brake pad against one side of the rotor. This action simultaneously causes the caliper to slide, or “float,” bringing the pad on the opposite side into contact with the rotor.

Fixed Calipers

A fixed caliper differs from a floating caliper in its immobility relative to the brake disc. A fixed caliper features pistons on both sides of the rotor, and this design can include multiple pistons per side. When the brakes are applied, hydraulic pressure causes the pistons on both sides to extend, pushing the brake pads against both sides of the rotor. This results in friction that slows down or stops the vehicle.

Sliding Calipers

Sliding calipers, also known as pin-slide calipers, share a similarity with floating calipers in having one or two pistons on just one side of the rotor. The key feature of sliding calipers is their use of pins or sliders, which facilitate the caliper’s slight back-and-forth movement during the braking process.

Brake Caliper Material

Brake calipers are typically made from two types of materials:

- Cast Iron: Known for its durability and heat absorption qualities, it’s widely used in standard vehicles.

- Aluminum: Lighter than cast iron and used in performance or luxury vehicles, aluminum calipers offer better heat dissipation and reduced unsprung weight, improving handling and efficiency.

Read More: What to Know About Aluminum Brake Calipers

PowerStop Powder Coated Calipers

Stand out from the crowd by enhancing your brake system with PowerStop Powder Coated Calipers, strikingly coated in vivid red electrostatic powder. These calipers are tailor-made for a perfect fit on your vehicle and undergo rigorous pressure testing to ensure they’re leak-proof. PowerStop calipers and brackets embody quality and durability. They’re equipped with high-temperature EPDM rubber seals and boots for an extended lifespan. For a straightforward and complete setup, PowerStop Powder Coated Calipers include bleeder screws and all necessary hardware for pad attachment. When all the components of the brake system are PowerStop, that will provide a performance boost vs mismatched components.

- Enhanced Braking Efficiency: Utilizing high-temperature EPDM rubber dust boots and top-quality silicone lubricant ensures smoother performance and prolonged durability under harsh conditions.

- Ready for Installation: These components are designed to fit directly onto your vehicle without any need for modifications.

- Complete Set Included: The package comes with everything required: new pistons, seals, slide pins (when applicable), dust boots, bleeder screws, and stainless-steel clips for brake pad abutment.

Brake Caliper Maintenance

Brake calipers require regular maintenance to ensure their optimal performance and safety.

Inspection

Regular inspection of brake calipers is crucial for identifying potential issues before they become serious. Key aspects to inspect include:

- Brake Pads and Rotors: Check for uneven wear, which can indicate a sticking caliper.

- Caliper Slides and Pistons: Ensure they move freely. Sticking or seized parts can affect braking efficiency.

- Brake Lines and Fluid: Look for leaks or fluid loss, which can compromise brake performance.

Routine inspections should be part of regular vehicle maintenance checks.

Cleaning

Keeping brake calipers clean is essential for their proper functioning. Dirt, debris, and road salt can cause corrosion and seizing. Steps for cleaning include:

- Remove Dirt and Grime: Use a brush and a specialized brake cleaner.

- Clean the Pistons and Slides: Ensuring these parts are clean prevents sticking and uneven wear.

- Inspect for Rust and Corrosion: Address any corrosion immediately to prevent further damage.

Cleaning should be done with appropriate safety gear, such as gloves and eye protection.

Bleeding Brakes in Case of a Soft Pedal Feel

If the brake pedal is soft or reaching down further than usual an inspection of leaks is required. Sometimes oxidation and thinning of fluid can occur and bleeding the brakes to get any air or contamination out of the system.

Lubrication

Proper lubrication is vital for the smooth operation of brake calipers. Key lubrication points include:

- Caliper Pins: These should be lubricated to ensure the caliper slides correctly.

- Piston Seals: Proper lubrication prevents drying out and cracking.

- Brake Pad Backing Plates: This helps reduce brake squeal.

- Pad Mounting Tabs: You may also need to lubricate the pad mounting tabs.

Use high-temperature brake grease or a lubricant specified for brake system components.

Replacement

Certain caliper components need replacement over time:

- Brake Pads: Replace them when they reach the minimum thickness recommended by the vehicle manufacturer.

- Caliper Hardware: Springs and clips should be replaced if they show signs of wear or damage.

- Calipers Themselves: If a caliper is severely damaged or continually problematic, replacing it may be necessary.

Replacement should always be done in accordance with the vehicle manufacturer’s specifications.

Should I Replace All Brake Calipers at the Same Time?

While you don’t necessarily need to replace all four brake calipers at the same time, it is generally considered a good practice to replace calipers in pairs (the front pair or rear pairs) for several reasons.

Why You Should Replace Calipers in Pairs

- Balanced Braking Performance: When one caliper is new and the other is old, they may not apply pressure to the brake pads with the same force. This imbalance can lead to uneven braking, where one side of the vehicle responds differently than the other, potentially causing the vehicle to pull to one side during braking. Replacing both ensures consistent braking performance on both sides of the vehicle.

- Even Wear on Brake Components: If calipers are not replaced in pairs, one side may wear out faster than the other. This can lead to uneven wear on the brake pads and rotors, necessitating more frequent maintenance and potentially higher costs in the long run.

- Similar Condition and Lifespan: Brake calipers undergo similar stress and environmental exposure on both sides of the vehicle. If one caliper has failed or is showing signs of wear, it’s likely that the other one is not far behind. Replacing both at the same time ensures that both calipers are in similar condition and have a similar lifespan.

- Cost-Effective in the Long Run: While replacing both calipers at once might be more expensive upfront, it can be more cost-effective in the long run. It saves on labor costs associated with doing two separate replacements at different times and reduces the likelihood of uneven wear on brake components.

Read More: How To Choose The Best Brake Calipers For Your Vehicle

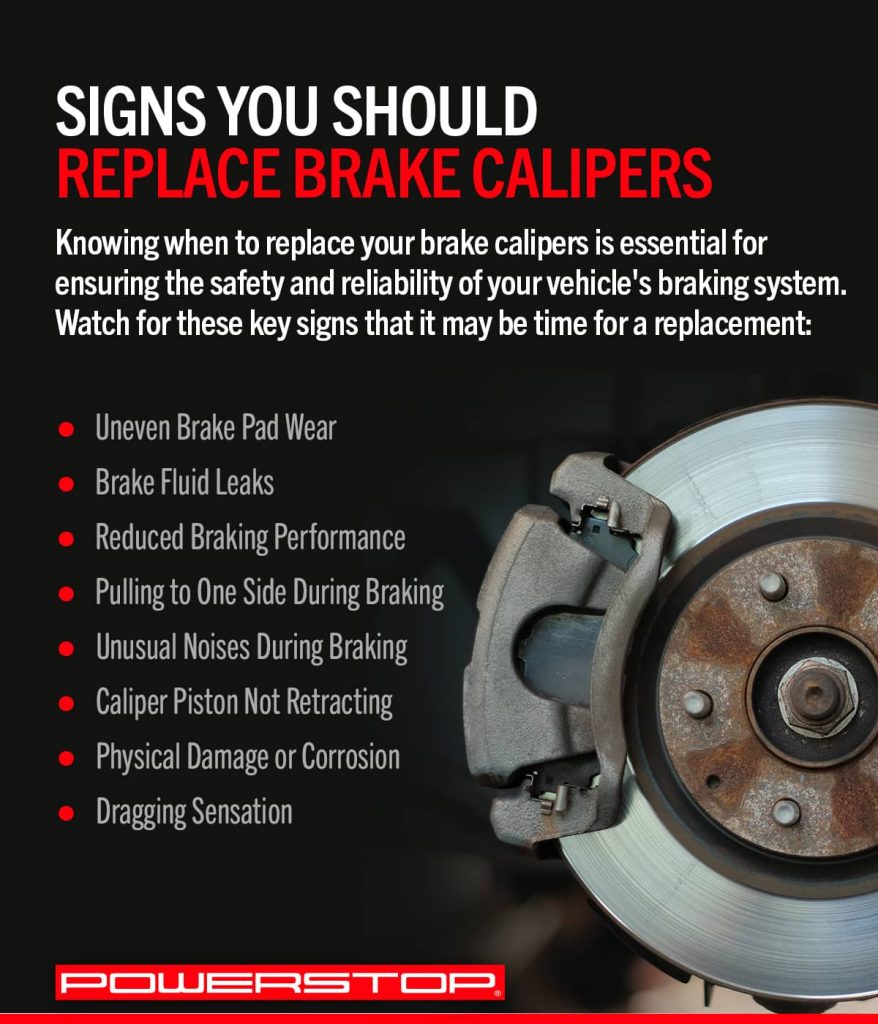

Signs You Should Replace Brake Calipers

Recognizing when to replace your brake calipers is crucial for maintaining the safety and effectiveness of your vehicle’s braking system. Here are some key signs indicating that your brake calipers may need replacement:

Uneven Brake Pad Wear

If you notice that one brake pad is wearing down faster than the others, it could be a sign that a caliper is not releasing properly, causing constant friction on one side.

Brake Fluid Leaks

Calipers use hydraulic brake fluid to function. If you spot leaks around the brake caliper area, this could indicate a failure in the caliper’s seals or a crack in the caliper itself.

Reduced Braking Performance

If your vehicle’s braking performance has noticeably declined, such as needing a longer distance to stop, it may be due to a failing caliper.

Pulling to One Side During Braking

If your vehicle pulls to one side when you brake, it might indicate that a caliper is sticking or seizing on that side, causing uneven braking pressure.

Unusual Noises During Braking

Squealing, grinding, or clunking noises during braking can sometimes be a symptom of caliper issues, often related to uneven pressure or a stuck caliper.

Caliper Piston Not Retracting

In a properly functioning brake system, the caliper piston should retract when you release the brake pedal. If it doesn’t, this could signify a problem with the caliper.

Physical Damage or Corrosion

Visible damage, severe corrosion, or rust on the caliper can impair its function and necessitate replacement.

Dragging Sensation

If it feels like your brakes are dragging or your vehicle is struggling to move freely, it might be due to a caliper that isn’t fully releasing.

Need to Replace Your Calipers? See Helpful Tips for Installing a New Brake Caliper

Have a Question? PowerStop Can Help!

PowerStop is dedicated to providing top-quality performance brakes for nearly every vehicle on the road. If you have a question about any of our products, contact us today online at [email protected] or toll-free at (888) 863-4415. Our customer service team is available to answer your questions Monday through Friday from 8 a.m. to 5 p.m. (CST). Se habla español.

Back