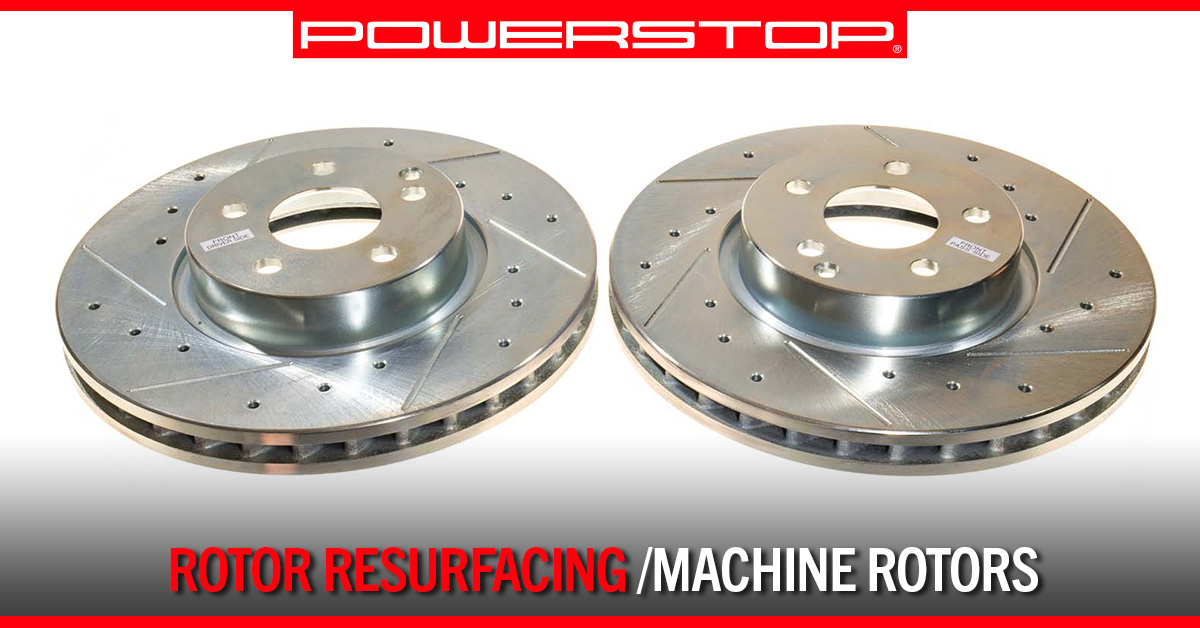

Rotor Resurfacing/Machine Rotors

Brake rotors incrementally lose some thickness whenever the brakes are applied. Although some people machine rotors to extend rotor life, there are downsides to resurfacing rotors instead of replacing them.

Machining can lead to poorer quality rotors and safety issues. The process is also time-consuming and can be difficult to do correctly. Below, we discuss the reasons why people choose to machine their rotors and explain the reasons why resurfacing rotors is concerning.

Can You Resurface Drilled & Slotted Rotors?

It is possible to machine or cut a drilled & slotted rotor. To do so, the brake lathe should be set to its slowest setting. Whenever brake pads are replaced, the rotors should also be replaced or resurfaced to allow the new pads to be properly bedded.

However, to ensure an optimal non-directional cross-cut finish, it is best to go with a new set of rotors from PowerStop. This will likely cost close to the same—and even possibly less than— cutting a rotor.

What Is Machining Rotors?

The term “machining rotors” refers to the process of removing metal to make the surface of a rotor flat again or to allow for a more uniform initial layer of friction with new brake pads being installed. The machining process usually starts with sanding the rotors with 120 grit sandpaper to remove built-up deposits and dirt. Then the surface of the rotor is resurfaced. This means that the rotor’s surface is cut, trimmed, and thinned on a lathe.

The last step of the machining process is testing. Following rotor resurfacing, the vehicle should be test-driven to ensure the rotors regained some level of friction.

Why Do People Machine Rotors?

Vehicle owners may choose to resurface their brake rotors for a number of reasons, such as:

- Increase stopping power: Rotor resurfacing is sometimes performed in an effort to regain friction and stopping power.

- Promote longevity: Some people machine their brake rotors to extend the rotor’s operational life.

- Reduce runout: Lateral runout describes the side-to-side movement of a brake rotor as it rotates. Brake pads and rotors can become worn when runout is excessive. Rotor resurfacing is sometimes performed to address this issue.

4 Reasons Why Resurfacing Rotors Is Concerning

If you have worn or damaged rotors, you may decide that machining them is a quick, inexpensive fix. The process of machining rotors removes layers of material to restore a flat, smooth surface. This is intended to provide the proper friction needed to allow for maximum pad contact and minimize noise-producing vibrations. However, there are a number of reasons why resurfacing rotors can be problematic for the function, quality, and safety of your braking system.

Reason 1: Quality

When rotors are machined, rotor thickness is pushed to the limit, making make them thinner, and susceptible to wear and overheating. Also, when rotor thickness varies, it causes imbalance, weight shifting, shaking, and vibrating.

Reason 2: Cost and Time

The cost to machine rotors might be greater than just replacing worn rotors with new ones. When resurfacing rotors, it is crucial to machine both rotors (a full set) to avoid imbalance. This process is time-consuming and may take multiple hours at the repair shop.

Reason 3: Safety

As stated above, rotor weight needs to be evenly distributed or else it leads to shaking and vibrating. It takes as little as .001 inches difference in thickness to notice when driving and braking. If rotors are machined too thin, they can damage brake parts. By machining the rotors to the maximum level, rotors will overheat, fade, and lose stopping power.

Reason 4: Not Getting Rotors to Resurface Properly

Some repair shops may resurface rotors as fast as possible. This can lead to mistakes in the process or result in too much metal being shaved off. Vibration can occur due to trimming metal off rotors or using worn bits to machine the rotors.

Signs of Worn or Damaged Brake Rotors

If you notice any of the conditions listed below, it may be time to replace your brake rotors. The most common signs that you may need new rotors include:

Squealing Sounds from the Brakes

If you hear high-pitched squealing when you engage the brake pedal, it is time to check your brake rotors. When a rotor becomes worn, uneven surfaces and edges are created on both the outside and inside of the rotor’s exterior. These affected surfaces and edges can cause squealing sounds during normal driving, but these sounds occur most frequently when force is applied to the brakes.

Longer Stopping Time

Worn brake rotors can create uneven surfaces, which prevents the brake pads from getting an adequate braking surface on the rotors. This dramatically reduces brake efficiency, causing vehicles to take longer to slow down and come to a stop.

Steering Wheel Vibrates When Braking

When front brake rotors start to go bad, you may feel your steering wheel vibrate while braking. These steering wheel vibrations can result from an imbalance caused by overheating or rust on the brake rotors.

Brake Pedal Pulsates When Braking

You can feel worn brake rotors in more places than just the steering wheel. If your brake pedal pulsates when the brake pedal is pressed, it may be due to uneven surfaces or rust on the brake rotors.

A pulsating brake pedal can be caused by either the front or rear brake rotors. However, if the problem is caused by the front rotors, you will likely also feel vibrations in the steering wheel.

Scratched, Scored, or Grooved Rotors

All brake rotors are susceptible to some amount of scratching, but if you notice a number of deep grooves, it is probably time to replace the rotors. Deep scratch marks can be caused by objects—such as stones—getting stuck between the brake pad and the rotor.

Large Edge on the Rotor’s Surface

An effective way to find out if a brake rotor needs to be replaced is to check the small edge on the brake rotor’s inner or outer surface. You can tell how much of the brake rotor is worn by comparing this edge to its condition when it was new. These edges can cause loud noises, so it is recommended to remove them if the brake rotor is not too worn and needs a replacement.

Blue Color on Rotors

Over time, excessive heat can turn brake rotors blue. Rotors often turn blue when calipers are locked, causing the brake pads to stay in almost constant contact with the metal. While this locking may be slight enough that you don’t notice any drag while driving, it can be enough to generate significant heat and wear.

Warning Lights

Warning lights can often be your first indication of a problem. There are a few different brake warning lights that can show up on your dashboard telling you it is time to inspect and possibly replace your worn-out brakes.

Your Mechanic’s Recommendation

Finally, if your trusted mechanic tells you it’s time for new brake rotors, you should listen. Car service professionals are highly trained and know what to look for when determining the health of a braking system and a vehicle’s overall condition.

Conclusion: Is it Better to Resurface or Replace Rotors?

Depending on the condition of the rotor, replacing rotors is a better option than resurfacing. Check out PowerStop’s high-quality performance brake kits and rotors! Do it yourself, replace your own rotors to save money, or bring PowerStop’s rotors to a reliable repair shop.

Have a Question? PowerStop Can Help

PowerStop is dedicated to providing top-quality performance brakes for every vehicle on the road. If you have a question about any of our products, contact us today online or toll-free at (888) 863-4415. Our customer service team is available to answer your questions Monday through Friday from 8 a.m. to 5 p.m. (CST). Se habla español.

Back